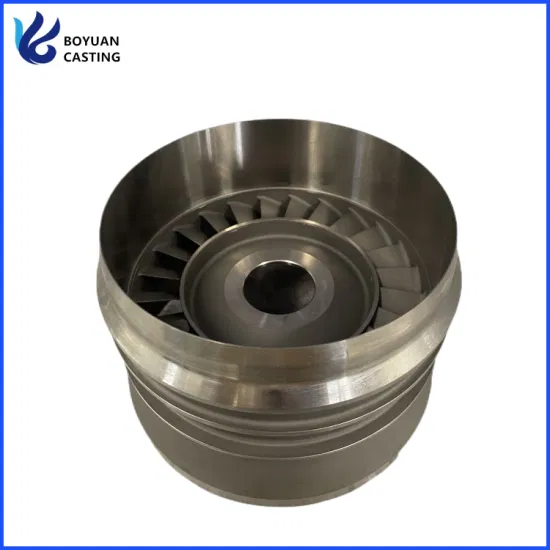

Customized Galvanized Precision Pressed Sheet Metal Parts Fabrication with Bending Process

OEM Stamping Part Feature of Stamping parts:1.Precision Stamping parts strictly according to customers request drawing; ;

Basic Info.

| Model NO. | MM-01 |

| Surface Processing | Polishing |

| Fine Blanking | Open |

| Process | Separation Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customized | Customized |

| Logistics Service | Sea, Air, Express, EXW, Fob, CIF, DDU, DDP |

| Application | Transportation |

| Surface | Coating, Painting, Plating, Polishing, or to Order |

| Quality Control | 0 Defects, 100% Inspection Before Packing |

| Delivery Time | 7-60 Days |

| Payment | T/T,L/C,Western Union |

| Design | According to Customers Requirement |

| Package | Carton or According Customers Prime; Requirement |

| Transport Package | as Per Your Requests |

| Specification | as per your drawing |

| Trademark | OEM |

| Origin | China |

| HS Code | 7326199000 |

| Production Capacity | 20000PCS/Day |

Product Description

OEM Stamping PartFeature of Stamping parts:1.Precision Stamping parts strictly according to customers request drawing;

2.Tolerance:Could be in +/- 0.02mm;

3.Quality assurance in accordance with ISO9001;4.Experienced technology engineers for 30 years & Well tranined workers;5.Production line is very professional with the special process;6.Fast and timely delivery:Speedly & Professional servie;7.Stamping Series: Stamped part, guard board, precision metal stamping, pressing parts with powder coated, pressing and welding parts, pressing and streching parts, pressing parts with glanvized.8.Porcessing: Stamping, punching, bending, welding, threading, grinding ,milling, machining, lathe,assembling etc.Products Description:

| Item name | Metal Parts |

| Manufacturer | Merid Machinery with advanced technology,professional skill and experienced technicians to fit our customers requirements. |

| Material | Iron, Aluminum, Carbon Steel, Brass, Stainless steel |

| Design | Use the advanced mould design software |

| Surface Treatment | self-color, galvanized,polishing,Zinc, powder coating, painting, nickle, chrome, polish, e-coating |

| Price Term | FOB QINGDAO |

| Delivery Time | 25-60 days based on the different products |

| Package | Caton,Wooden Case or as Required |

| Industry | Customized parts are used in Building,Automotive,Electrical,Machiner assembly,Furniture,Aoil field Equipments,Marine equipments,Agricultural Machines,Transportation Equipment,OEM/ODM Electronics......... |

The other products:

Workshop:

Company information:

Qingdao Merid Machinery Co.,Ltd was established in Qingdao, China in 1991, with and area of 56,000 square feet. We are a professional top provider and industrial leader of full-service stamping, welding, machining, die castings and fabrication of metal components.The fields covers:1.Automotive parts2.Medical parts3.Agricultural parts4.Stock farming parts5.Architectural parts6.Industrial parts7.Special Fields8.Energy Industry9.Telecommunication10.Optical Semi-Conductor11.Appliance12.Lighting13.AerospaceMerid is equipped with the in-house capabilities of taking your project from design - tooling - prototype - production to finish, and the professional technical and production team could provide you the best solutions to ensure high quality and cost effective production of your products.

Our Advantage:1.Good Quality,Competitive Price2.Long production history, International Quality Certified3.Skilled workers,Prompt Delivery Time4.Warranty After-sales-service

Package:

FAQ:1.What are our advantages over others?a). Stamping, Machining, Welding, Die casting and Surface treatment equipment are equipped for providing you our best service and solutions.b). 45 years experience.c). On-time delivery.e). Strict Quality Control System: 100% inspection before the shipment..2.What are the production capacity of your company?a). In Merid, fabrication works include precision stamping, deep drawing, fine blanking, cnc punching, cnc bending, laser cutting, flame cutting, cnc milling, cnc turning, tube bending, aluminum extruding, welding, die casting, etc.b). Metal materials include stainless steel, iron, carbon steel, spring steel, aluminum, titanium, copper, brass, bronze etc.3.What equipments do you own?a). Punch Press: 16T-400T.b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).d). Die casting: 80T-500T.e). Surface treatment: Shot blasting facility, Polishing, Deburring.4.What finishes can you provide?The finishes which we could provide is powder coating, painting, galvanizing, baked enamel, anodizing finish, and other plating finishes.5.How can you guarantee the quality?Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.Welcome contact us to start our cooperation!

You may also like

Send inquiry

Send now